Lotus-inspired superhydrophobicity attracts the interest of researchers due to their interfacial non-wetting and unique multi-phase contact properties. However, fragile hierarchical structures, fluorine-containing chemicals usage, and strict requirements for substrate scopes remain thorny challenges.

Thus, achieving water-repellent superhydrophobic coatings with improved mechanical robustness utilizing fluorine-free chemical reagents and substrate-independent processes is crucial and urgent for real-world applications of superhydrophobic materials.

Recently, the research team led by Prof. HOU Baorong and Prof. DUAN Jizhou from the Institute of Oceanology of the Chinese Academy of Sciences (IOCAS) reported a mechanical robust superhydrophobic ZnO@STA@PDMS coating with fluorine-free reagents through wide-applicable and substrate-independent spray-coating method.

The study was published in Materials & Design on Oct. 10.

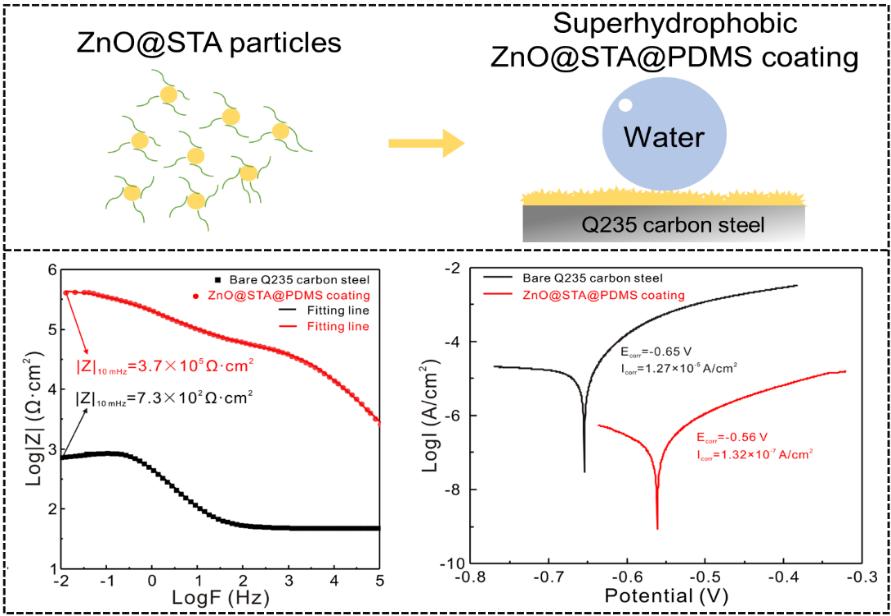

The hierarchical rough micro-scale bump-porous structure, nano-scale particles and extremely low surface energy of the coating contribute to the eventual water repellent superhydrophobicity. The |Z|10mHz value of the as-fabricated superhydrophobic coating is 3.7 × 105 Ω·cm2, which is 3 order of magnitudes higher than Q235 carbon steel (7.3 × 102 Ω·cm2). The Icorr of the substrate decreases 2 orders of magnitude after spray-coated with superhydrophobic ZnO@STA@PDMS coating, suggesting a superior corrosion resistant performance. Furthermore, the prepared superhydrophobic coating can withstand more than 30 tape-peeling cycles and 400 cm abrasion distance, demonstrating good mechanical stability.

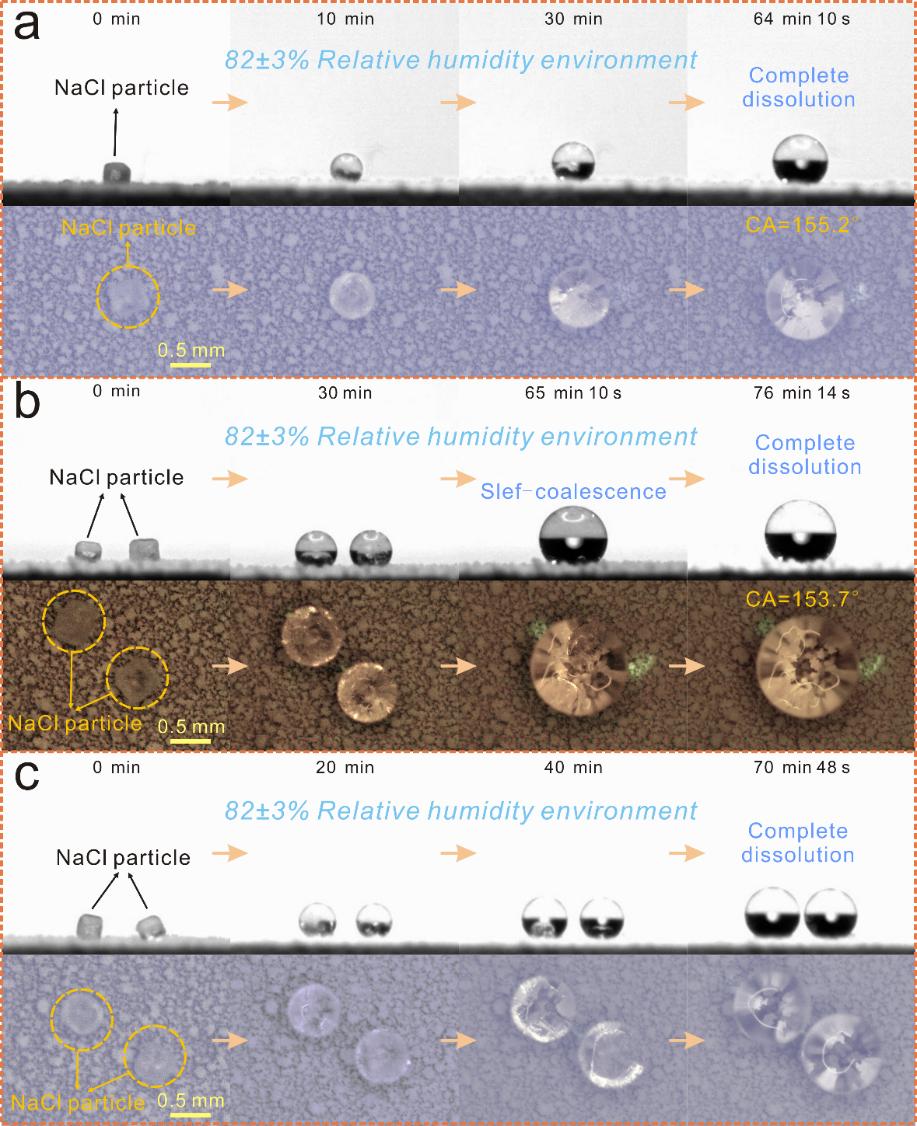

Besides, in simulated marine atmospheric conditions with high relative humidity, the hygroscopic and deliquescence behaviors of NaCl salt particles were firstly recorded and showed an interesting instantaneous self-coalescence phenomenon. The corrosion damage in the edge of saline droplet on bare Q235 carbon steel is more severe than interior because of faster ions transfer and abundant oxygen. While the superhydrophobic coating possesses promising atmospheric corrosion inhibition performance based on salt-deliquesce and instantaneous self-coalescence phenomenon.

The low interfacial adhesion force, low surface energy and air cushion-induced Cassie multi-phase contacts contribute to the saline droplet anti-wetting and remarkable anti-corrosion capability. "This phenomenon provides a new type of anti-corrosion mechanism for superhydrophobic materials served in marine atmospheric environment with high relative humidity, and guides future research of this field," said Associate Prof. ZHANG Binbin, the first author and corresponding author.

This study was supported by the Shandong Provincial Natural Science Foundation and the Youth Innovation Promotion Association of Chinese Academy of Sciences.

Fig. 1 The schematic illustration of the fabrication process and the corrosion resistant properties of the superhydrophobic coating.

Fig. 2 Deliquesce behaviors of NaCl salt particles on superhydrophobic coating.

Fig. 3 Wide-adaptability of the as-prepared superhydrophobic coating on different substrates.

B. Zhang*, J. Yan, W. Xu, Y. Zhang, J. Duan, B. Hou, Robust, scalable and fluorine-free superhydrophobic anti-corrosion coating with shielding functions in marine submerged and atmospheric zones, Materials & Design, 2022, 223, 111246.

(Text by ZHANG Binbin)

Media Contact:

ZHANG Yiyi

Institute of Oceanology

E-mail: zhangyiyi@qdio.ac.cn

(Editor: ZHANG Yiyi)