The powder thermal diffusion alloying method is an important surface strengthen method which can fabricate an anticorrosion coating on magnesium alloys. The diffusion time for most diffusion alloying processes varies from tens of minutes to hours. Meanwhile, it is hard to tell whether the diffusion source has already failed or not in the end of the diffusion alloying process.

Recently, the research team led by Prof. HUANG Yanliang from the Institute of Oceanology of the Chinese Academy of Sciences (IOCAS) clarified the effective time of a diffusion source which contains 10 g ZnO and 1 g NH4Cl at 400 ℃. Surprisingly, the effective time of such a diffusion source can be longer than 150 hours.

The study was published in Journal of Materials Research and Technology on Apr. 25.

Results show that a looser and purer diffusion source and a better air tightness of the crucible are inferred to be helpful to prolong the effective time of the diffusion source. A longer preheating time of the diffusion source is preferred for the fabrication of a thicker Zn-rich diffusion alloyed coating in the first diffusion alloying process.

Moreover, continuous consumption of the active phase at elevated temperatures leads to the failure of the diffusion source. While, it is proved in this work that such an inactive diffusion source could be reactivated by adding new NH4Cl powder.

"Clarification of the effective time of the diffusion source at elevated temperatures in this work is quite meaningful to save powder materials as well as optimize the diffusion alloying operation in related industries", said Dr. LU Dongzhu, first author and corresponding author of the study.

This study was supported by the National Natural Science Foundation of China, the Wenhai Program of the S&T Fund of Shandong Province for Pilot National Laboratory for Marine Science and Technology (Qingdao), etc.

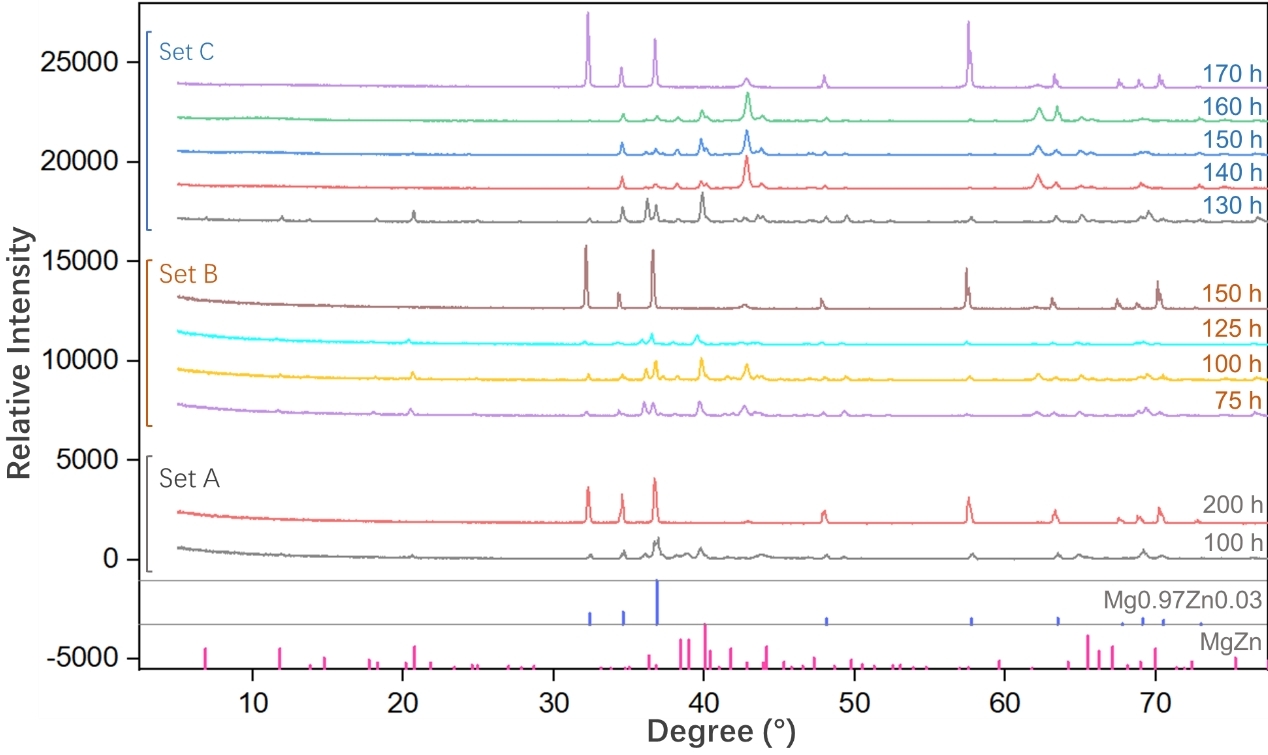

Fig. 1 XRD (X-ray diffraction) patterns of Mg alloy specimens after diffusion alloying processes.

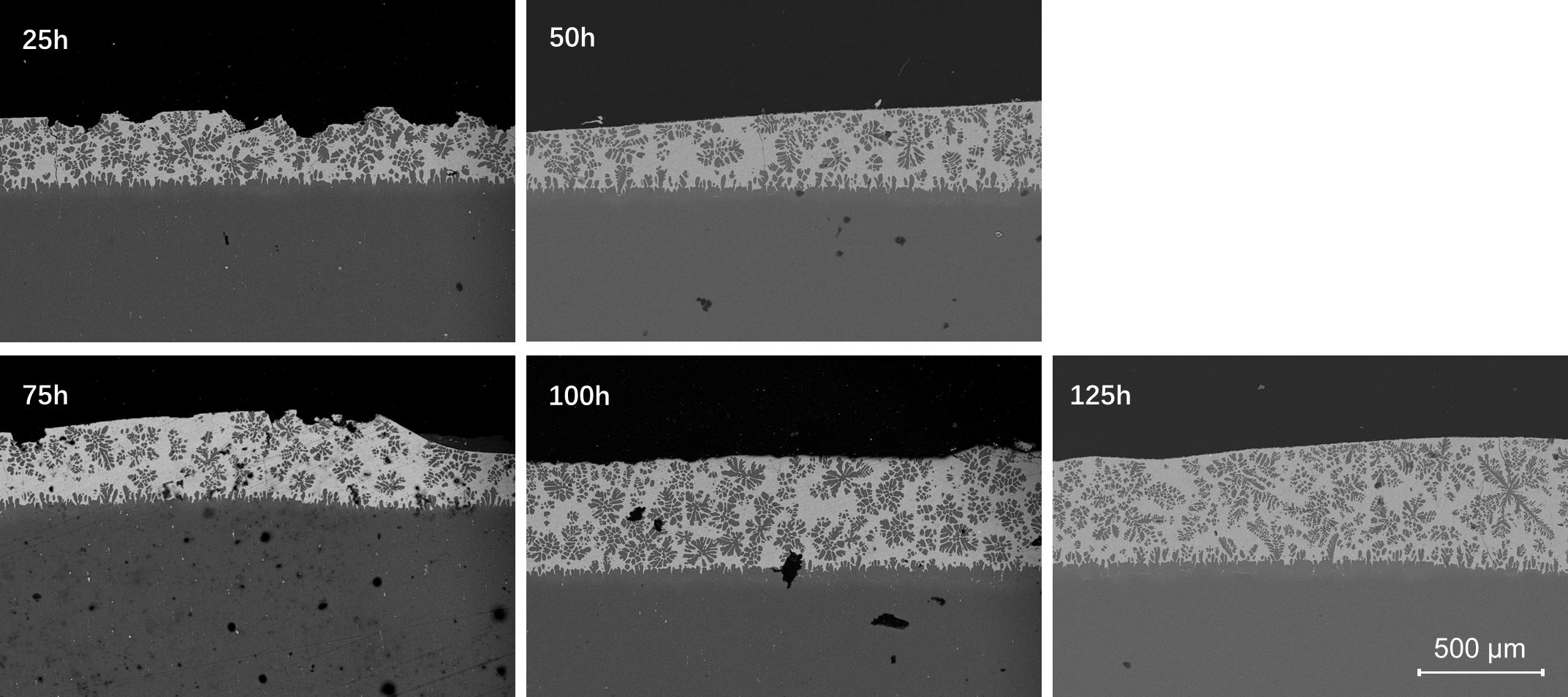

Fig. 2 The as obtained Zn-rich coatings fabricated on Mg alloy specimens after the first diffusion alloying process with a pre-sintering time of 25 h, 50 h, 75 h, 100 h and 125 h for the diffusion source. All the photographs share the same scale bar at the lower right corner.

D Lu*, Q Jiang, X Ma, L Fan, Y Huang*, B Hou. (2023). Effective Time of a Diffusion Source in a Pack Cementation Process on the AZ91D Magnesium Alloy. Journal of Materials Research and Technology.

(Text by LU Dongzhu)

Media Contact:

ZHANG Yiyi

Institute of Oceanology

E-mail: zhangyiyi@qdio.ac.cn

(Editor: ZHANG Yiyi)